RCFS

Radio Control Fail-Safe

RCFS

is a tiny microcontroller based device that adds Fail-Safe features

to any PPM (AM/FM) radio control system. It is very simple to build

-- only three components!

Expensive

PCM based R/C receivers have the ability to detect radio reception

problems. On these systems, if the signal integrity is poor, the

servos' positions can be programmed to default to emergency

conditions.

However,

Fail-Safe is not a common feature on the lower cost PPM systems. The

Multiplex IPD

Receiver family offers it, but none of the other radio makers

have bothered to add it to any of their standard R/C systems.

However, with the RCFS device discussed here, you can add Fail-Safe

to ANY servo that is used on a standard PPM (AM or FM)

radio control system. Cost is less than $3 per channel.

What Goes Up Must

Come Down

The intent

of any Fail-Safe system is to help reduce the danger that might

occur when a model aircraft loses radio contact. Regardless of how

you may personally feel about PCM radios and their Fail-Safe mode, I

believe that most folks agree that programming an out-of-control

model to slow down is not a bad idea.

The model

will still crash, but hopefully the reduced speed will give it, as

well as the folks on the ground, a better chance to survive the

mayhem. It probably does not hurt to help stabilize the uncontrolled

servos too, something that a Fail-Safe will also do for you.

Unlike the

more sophisticated PCM systems, the RCFS can NOT be used to help

clean up a "noisy" R/C installation. If your model is plagued with

erratic servo glitches then do not expect this device to tame your

problems. Yes, a PCM system would help, but blindly fixing the

glitches with PCM is often considered a mistake by most experienced

R/C'ers. That sort of discussion has already filled megabytes of

space on the popular R/C forums, so I will not comment any further.

The bottom line is that the RCFS will not help you in this

area.

The

Fail-Safe behavior on RCFS differs from what you would experience on

a typical PCM system. We will talk about that in a moment. But for

now, let me say that the RCFS attempts to address some common

complaints. Most importantly, I wish to make it clear that using the

RCFS device, or any other Fail-Safe system, is at YOUR risk.

Control

Freak

RCFS is

installed between the R/C receiver and servo. It constantly analyzes

the incoming servo pulses and looks for serious trouble. Using a

microcontroller, the pulses are checked to see if they fit within a

allowable range, in a template sort of fashion. If the pulses

are found to be acceptable, they are merely passed along to the

servo. You will have full control of the model and RCFS remains a

passive passenger at this point.

If the

pulses are missing (lost signal) or invalid (noisy signal) then the

RCFS attempts to determine the extent of the trouble. If the problem

persists for more than a second the Fail-Safe feature is enabled.

During Fail-Safe, RCFS takes control of the servo position. It can

be set to hold the last valid position or it can move

the servo to a preset position.

Complaint

Department

My approach

attempts to minimize the Fail-Safe's intervention. One of the common

complaints with PCM Fail-Safe is that it totally masks reception

troubles, especially the brief intermittent type. On a PPM system,

these sort of "glitches" can be felt, so detecting trouble

before things get out of hand is easier to recognize. I too

believe that it is an advantage to be able briefly witness most

glitches.

It is for

this reason that the RCFS has been designed to NOT mask any brief

periods of radio "hits." Random radio hits will be felt during the

short windowing period. If the servo signal consists of a collection

of good and bad pulses, the RCFS will do its best to remain off in

order to allow you to "fly through" the noise. For sure, totally

loss of radio contact will cause the Fail-Safe to switch on after

the brief delay.

Note:

Noisy signals that contain substantial amounts of valid servo pulses

will not activate the Fail-Safe mode. This can be a blessing or a

burden, depending on the situation. As I mentioned, this is so that

your stick commands have a chance of getting through. A PCM system

would either (1) mask the corrupted signals or (2) switch to

Fail-Safe in extreme situations.

Timing is

Everything

The servo signal is

a simple digital pulse. It spends most of its time at a logic low

(0V). About every 20mS it goes logic high (4-6VDC) and then quickly

goes low again. It is this tiny window of logic high time, called

the pulse width, that gets the attention of the servo. The servo signal is

a simple digital pulse. It spends most of its time at a logic low

(0V). About every 20mS it goes logic high (4-6VDC) and then quickly

goes low again. It is this tiny window of logic high time, called

the pulse width, that gets the attention of the servo.

Please

refer to the drawing. The period labeled "A" is called the frame

rate. In the example it is repeated every 20mS (50 times per

second), which is quite typical for many radio systems.

Modern

servos define center as a 1.5mS pulse width, as shown by detail "B"

in the drawing. Full servo rotation to one side would require

that this pulse width be reduced to 1.0mS. Full rotation to the

other side would require the pulse width to increase to 2.0mS.

In the eyes

of RCFS, good servo pulses will be between 0.75mS and 2.25mS long.

Even though a normal servo signal is 1.0mS to 2.0mS, some

transmitters offer ATV settings that can extend the timing beyond

that. The wider range taken by RCFS allows compatibility with such

radio systems.

When servo

pulses do not fall within the allowed range, they are flagged as

"corrupt." When corrupt pulses are encountered, they are monitored

for a one second period to ensure that there is sufficient cause to

switch to Fail-Safe. The threshold before switching to Fail-Safe is

managed by a complex software algorithm that was developed

specifically for this project.

Lost and

Found

Besides the

Fail-Safe feature, you can also upgrade RCFS to include a Lost

Model Finder feature. All it takes is a transistor and a loud

Sonalert type piezo transducer. If you do not need the Fail-Safe

support then a single IC circuit is all that is needed to make a

complete Lost Model Finder. The schematic shows the details.

With the

Lost Model Finder option you will be able to locate your downed

aircraft simply by turning off the R/C transmitter. Just listen for

the screaming beep tone. You may not be able to see it, but you will

now be able to hear where the model is hiding.

Less is

Best

The parts

count in this project is minimal. All it takes is an 8-pin PIC

microcontroller, 14-pin CMOS Nand Gate IC, 3-position DIP switch,

and a capacitor. Shopping for these parts will be a breeze, since

they are all available at Digi-Key. Your wallet will be

happy too, since material cost is very low.

The chosen

microcontroller is from the vast offerings of Microchip Technology. Actually,

your exact PIC choices have some flexibility. You can use a

PIC12C508, PIC12C508A, PIC12C509, or PIC12C509A.

The

PIC12C50x is not a "Flash" part, so you will need a traditional PIC

chip programmer to "burn" the hex file's object code into the

microcontroller. Be sure to select the configuration fuses during

chip burning as follows (these are optional settings within your

chip programmer's menus):

|

WDT: |

Disabled |

|

MCLR: |

Disabled |

|

Oscillator: |

IntRC |

|

Memory: |

Protected |

The CD4011 Nand

Gate is used as a 2:1 signal Mux. The PIC's SIG_OK control line

determines the Mux's signal source (R/C receiver or PIC Fail-Safe).

Please note that Pin 14 connects to +V and Pin 7 is ground.

The DIP

switch is used to enabled the Fail-Safe preset positions. It is

actually three little SPST slide (or rocker) switches in a

single package. You could also use a header with shorting blocks, or

simply use jumper wires if you do not need to change the settings.

The switch settings are as follows (ON = CLOSED, OFF = OPEN):

| SETTING |

POS2 |

POS1 |

POS0 |

Fail-Safe MODE |

PULSE WIDTH |

|

0 |

ON |

ON |

ON |

Fail-Safe HOLD |

-- |

|

1 |

ON |

ON |

OFF |

Preset Mode, -60º |

1.0mS |

|

2 |

ON |

OFF |

ON |

Preset Mode, -40º |

1.2mS |

|

3 |

ON |

OFF |

OFF |

Preset Mode, -20º |

1.3mS |

|

4 |

OFF |

ON |

ON |

Preset Mode, 0º (Center) |

1.5mS |

|

5 |

OFF |

ON |

OFF |

Preset Mode, +20º |

1.7mS |

|

6 |

OFF |

OFF |

ON |

Preset Mode, +40º |

1.8mS |

|

7 |

OFF |

OFF |

OFF |

Preset Mode, +60º |

2.0mS |

RCFS

Construction:

Even though

it is very simple, this project is best tackled by an experienced

electronic technician. If you have successfully built any of the

other RC-CAM Electronics Projects

then you should have no problem with this one. Entry level

technicians should plan on getting some hands-on help.

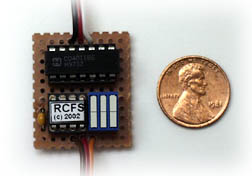

The RCFS

board can be built using nearly any technique you wish. It really

deserves a printed circuit board, but mine was built on a tiny piece

of phenolic perf board. Be sure that your construction technique is

worthy of a model aircraft's environment.

Layout is

not critical.  The circuit was point-to-point

wired using 30 gauge insulated Kynar wire. This wire is normally

used for wirewrapping, but works fine with a soldering iron. I

recommend a temperature controlled iron (700° tip). The circuit was point-to-point

wired using 30 gauge insulated Kynar wire. This wire is normally

used for wirewrapping, but works fine with a soldering iron. I

recommend a temperature controlled iron (700° tip).

The circuit

can be hardwired to a servo's cable. However, I used a six inch

servo extension that was cut in half. Installation in the model

plane is a plug-and-go sort of effort.

Check it

Out

Simple

mistakes can destroy electronic parts and may generally ruin your

day, so check your work carefully. Do not install the receiver

battery until you have verified that the power leads are not shorted

(use an ohmmeter). If all looks good, plug the RCFS into a channel

of your PPM receiver.

Do NOT

install the PIC chip until you have verified that U2 pin 8 is ground

and the pin 1 has 4.5 to 6.0 VDC on it when a battery is connected.

Remove the battery BEFORE you install the chip.

Now it's

time to test your work. Just follow these simple test steps:

- Turn on

your transmitter and verify that the stick controls the servo.

- Turn off

the transmitter. In approximately one second, the servo should

"Fail-Safe."

- Turn on

the transmitter and verify control is regained within a

half-second.

- Repeat

the test for all eight combinations of the DIP switch

settings.

Design

Documents:

The

technical details are available as file downloads. There is no

charge for the information when used in a personal (hobby) project.

Commercial users must obtain written approval before use.

Please be

aware that the information is copyright protected, so you are not

authorized to republish it, distribute it, or sell it, in any form.

If you wish to share it, please do so only by providing a link to

the RC-CAM site. You are granted permission to post links to the web

site's main page (http://www.rc-cam.com/). Please

respect this simple request.

|

Schematic Files: PDF file of the RCFS circuitry.

All major components are from http://www.digikey.com/.

Revision: Rev A, dated 06-17-2002 |

|

PIC Object Code: Hex file of the compiled RCFS

firmware. You should occasionally check for updates.

Revision: V1.0, dated

06-17-2002. |

The Small

Print:

| If

you need a part then please consult the sources shown in the

project (see schematics download). I do not work for, nor

represent, ANY supplier of the parts used in RCFS. Any

reference to a vendor is for your convenience and I do not

endorse or profit from any purchase that you make. You are

free to use any parts source that you

wish. |

All

information is provided as-is. I do not offer any warranty on its

suitability. That means that if you build and use this device, you

will do so at your own risk. If you find documentation or software

errors then please report them to me. |